|

We strive to build highly efficient press lines and establish processes that take full advantage of them to achieve low costs while also establishing safe working environments. Furthermore, we work to achieve lighter product weights through press molding using ultra-high tensile strength materials. |

800-ton servo press

800-ton servo press features and advantages

Sliding motion can be freely adjusted to optimize for machining needs, enabling vast improvements in molding performance, productivity and other areas. We plan to utilize these advantages to pursue weight reductions through high-tensile-strength material molding, enable use of lower-grade materials by enhancing molding freedom, and take other such measures in pursuit of cost reductions.

300-800 ton fully automated press line |

60-160 ton progressive line |

|

|

|

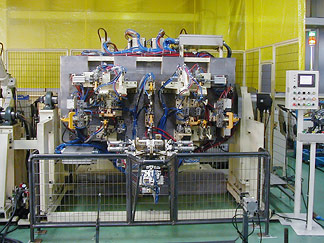

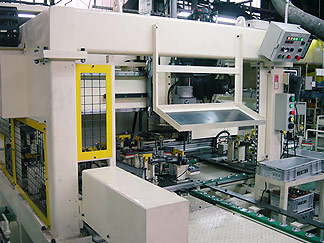

By constructing assembly lines that utilize welding robots and automating caulking equipment operations, we achieve stable welding quality and reduce personnel and labor requirements. In addition, we strive for efficient utilization and movement of goods throughout the entire factory while always focusing on safety in equipment layout design. |

Robotic arc welding line |

Spot welding line |

|

|

Caulking equipment |

TOX equipment |

|

|

Futaba Kogyo carries out assembly of moving parts for roadster RHTs (retractable hardtops). By automating caulking equipment, we are able to reduce personnel and labor requirements. |

|

In order to synchronize manufacturing operations and part provision with customer plans, we introduced a synchronized component delivery system. This makes it possible to reduce in-process inventories, conserve space, and reduce personnel and labor requirements through utilization of AGVs (automated guided vehicles). |

Sequenced delivery system

In our continuing pursuit of cost reductions, we made full use of automation in a tandem press line format rather than switching to progressive or transfer lines.

Depending on the product being made, some press machines are left unused at times in tandem press lines. By utilizing these unused machines in different production cycles, it has become possible to attain much higher levels of productivity.

The multiple-piece production system makes it possible to achieve such high productivity, and this approach contributes toward significant cost reductions.

Depending on the product being made, some press machines are left unused at times in tandem press lines. By utilizing these unused machines in different production cycles, it has become possible to attain much higher levels of productivity.

The multiple-piece production system makes it possible to achieve such high productivity, and this approach contributes toward significant cost reductions.

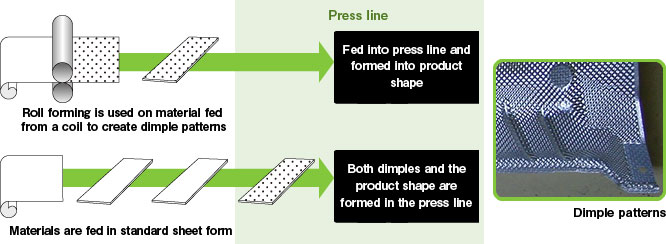

Production operations on a standard press line without introducing new equipment.

This makes top-level cost performance possible.

This makes top-level cost performance possible.

Production operations on a standard press line without introducing new equipment.

This makes top-level cost performance possible.

This makes top-level cost performance possible.